Website Design Copyright 2025 © 竹新化學股份有限公司 & 頂烽企業股份有限公司

All Rights Reserved. 網頁設計 by 覺醒設計

TaipeiPLAS 2024 officially opened on September 24 at the Taipei Nangang Exhibition Center. The five-day event brought together nearly 500 exhibitors from the global rubber and plastics industry, utilizing over 1,800 booths to showcase the latest technologies and products. This year's exhibition attracted over 16,000 domestic and international professionals, including more than 2,500 buyers from countries such as India, Myanmar, Vietnam, Malaysia, and Egypt. The bustling business discussions underscored TaipeiPLAS's influence in the Asian rubber and plastics market. Among the participating nations, the top five buyer countries were India, Japan, Thailand, Vietnam, and China.

APEX-TW joined forces with ICMT and APEX-VN to showcase the latest calcium carbonate and inorganic powder technologies at the Taipei Nangang Exhibition Center during the 2024 Taipei International Rubber & Plastics Industry Exhibition. The event brought together global experts, industry leaders, and innovators to explore advancements in material technologies and their applications. As Taiwan's leading supplier of calcium carbonate and inorganic powders, APEX-TW is dedicated to providing high-quality, eco-friendly material solutions. ICMT focuses on driving innovation in advanced material technologies, enhancing performance and durability. Meanwhile, APEX-VN leverages its production and supply strengths in Vietnam to support the rubber and plastics industries in Southeast Asia and worldwide with reliable, high-quality materials.

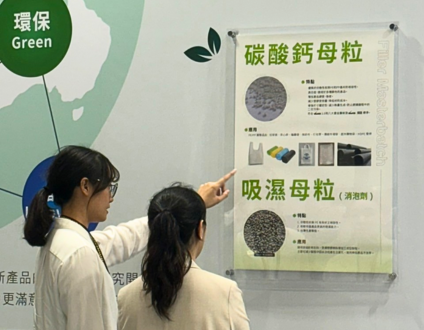

Together, APEX-TW, ICMT, and APEX-VN highlighted cutting-edge innovations in inorganic powders and masterbatch technologies. These include highly durable and stable calcium carbonate masterbatch and masterbatch, designed to enhance product performance, reduce costs, and drive technological advancement in the rubber and plastics industry. By addressing critical market needs, the collaboration strengthens the competitive edge of businesses across Southeast Asia and global markets. Their joint presentation showcased groundbreaking innovations, such as advanced technologies that significantly improve weather resistance, abrasion resistance, and environmental sustainability. These innovations meet the stringent demands of the rubber and plastics industries while reducing production costs, minimizing carbon emissions, and easing environmental impact.

During the exhibition, the collaboration between APEX-TW, ICMT, and APEX-VN further underscored their technological integration capabilities. Whether in product development or market expansion, their united efforts enable customers to stay ahead in competitive markets. The joint display also demonstrated how APEX-TW, ICMT, and APEX-VN utilize innovation and resource integration to provide diverse and efficient material solutions.

Through this exhibition, APEX not only showcased its exceptional technical expertise but also highlighted its ambition to expand its global presence. This partnership with ICMT and APEX-VN emphasizes the company’s long-term strategy in the global rubber and plastics industry. APEX-TW, ICMT, and APEX-VN aim to leverage this event to strengthen their international influence, collaborate with global partners, and drive sustainable growth in the rubber and plastics industry. This joint participation signifies a commitment to becoming a key provider of core technologies and solutions in the global rubber and plastics market.

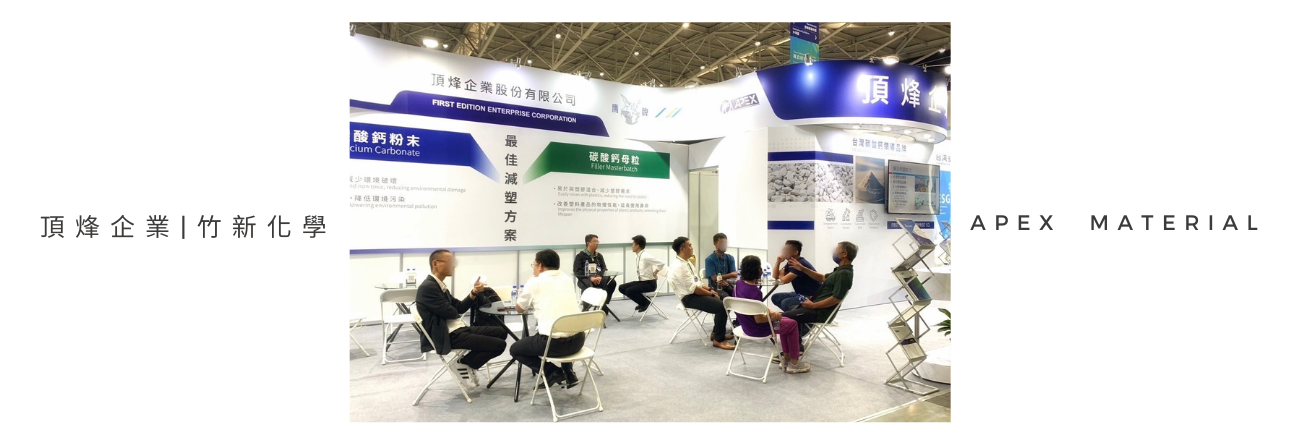

APEX-TW, ICMT, and APEX-VN focused on showcasing calcium carbonate masterbatch, inorganic powder, and masterbatch technologies. These innovations significantly improve weather resistance, abrasion resistance, and environmental performance, helping rubber and plastics companies enhance product quality while reducing production costs. APEX-TW’s team provided one-on-one professional guidance during the exhibition, explaining the application of these technologies and how they can boost product stability, extend lifespan, and meet stringent environmental standards.

The exhibition drew global rubber and plastics experts, captivated by Taiwan's reputation as the "Kingdom of Plastics." APEX-TW showcased high-quality calcium carbonate and masterbatch, enhancing durability, processing performance, and anti-aging in applications. APEX-TW’s innovations sparked industry discussions, attracting international buyers. On-site, the expert team provided tailored consultations, demonstrating the products' role in advancing the global industry. Many buyers expressed interest in long-term partnerships, promoting sustainable development together.

Located in the Hsinchu Science and Technology City, Taiwan, occupying an area of 15,000 square meters, Chu Shin Chemical originated its manufacturing with the production of Precipitated Calcium Carbonate and boasts a history of over 50 years in Taiwan.

Currently, Chu Shin Chemical operates two calcium carbonate production lines, manufacturing Precipitated Calcium Carbonate, Ground Calcium Carbonate, and Powder Surface Treatment Calcium Carbonate.

Additionally, there are two lime production lines producing Quicklime and Hydrated Lime.

With a monthly total production capacity of 20,000 tons, Chu Shin Chemical stands as a key player in the production of calcium carbonate and lime products.

In 2019, APEX-TW established APEX MATERIAL INDUSTRIAL VINA CO., LTD in Binh Duong, Vietnam, spanning an area of 30,000 square meters.

The facility operates 8 calcium carbonate production lines, manufacturing Precipitated Calcium Carbonate, Ground Calcium Carbonate, and Powder Surface Treatment.

Additionally, there are 2 Plastic composite materials production lines, producing Calcium Carbonate Masterbatch and PVC Compund. A single PP Woven Bag production line is dedicated to the manufacturing of PP woven bags.

With a monthly powder production capacity of 40,000 tons and a Masterbatch production capacity of 8,000 tons, APEX-VN is equipped to meet diverse industrial needs.

(For more details, please visit the official websites of APEX-VN)

In 2018, APEX-TW established ICMT (INNOVATION COMPOUND MATERIAL TECHNOLOGY LTD), specializing in the production of Calcium Carbonate Masterbatch and Talc Masterbatch.

ICMT serves as a supplier to the plastic industry in Taiwan, with a monthly production capacity of 17,000 tons.

(For more details, please visit the official websites of ICMT. )

We use cookies to collect and analyze information on site performance and usage. By Clicking "Continue" or by clicking into any content on this site, you agree to allow cookies to be placed. To find out more, please visit our privacy policy。

CONTINUE GO TOP

GO TOP